BHP, a prominent multinational mining corporation with a significant presence in Western Australia, is renowned for its commitment to safety and innovation. In this context, ensuring accessibility and safety for employees and visitors was a top priority. To meet these objectives, BHP partnered with Dottac, a leading company specializing in tactile solutions. Dottac’s innovative use of stainless steel tactile indicators with carborundum played a pivotal role in enhancing accessibility and safety at BHP facilities in Western Australia.

BHP’s operations in Western Australia encompass a vast and dynamic industrial landscape, including mines, processing facilities, and corporate offices. With a focus on fostering a safe and inclusive environment, the company recognized the importance of addressing accessibility for employees, contractors, and visitors.

Tactile indicators are essential tools for enhancing accessibility and safety in industrial and corporate settings. They provide tactile cues and sensory information to individuals with visual impairments, facilitating navigation and reducing the risk of accidents. The incorporation of tactile indicators at BHP’s facilities was a significant step toward achieving these goals.

Dottac’s involvement in the project began with a comprehensive assessment of BHP’s facilities in Western Australia. This assessment aimed to identify key areas where tactile indicators could have the most significant impact on accessibility and safety. Collaborating closely with BHP’s safety experts and accessibility consultants, Dottac ensured that the installation would be tailored to meet the unique requirements of industrial and corporate settings.

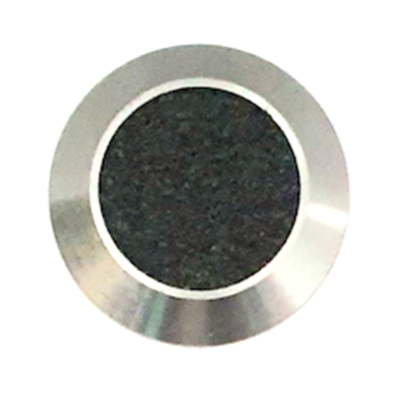

One of the primary areas of focus was the entrances to BHP facilities. Dottac strategically installed stainless steel tactile indicators with carborundum at the entrances, marking the transition from the exterior to the interior. These tactiles provided clear and tactile cues, making it easier for employees, contractors, and visitors with visual impairments to locate and access the main entrances independently.

Inside the facilities, tactiles were placed strategically to guide individuals toward various areas, including workstations, offices, meeting rooms, and emergency exits. These indicators formed tactile pathways, ensuring that everyone could navigate the facilities with confidence. The tactiles incorporated carborundum, a highly durable and slip-resistant material, to enhance safety in industrial and corporate environments.

The choice of stainless steel for the tactile indicators was not only practical but also added a touch of modernity and sophistication to the facilities. Stainless steel is known for its durability, resistance to corrosion, and sleek appearance, making it an ideal material for industrial and corporate settings.

Staircases, often present in industrial facilities and corporate offices, were another area of focus. Dottac addressed this by installing tactile indicators on staircases throughout BHP’s facilities. These tactiles featured raised dots and tactile patterns that clearly defined each step, enhancing safety and accessibility in areas with potential hazards.

Elevators, an essential feature in multi-story corporate buildings, also received Dottac’s attention. Tactile indicators were strategically positioned near elevator doors, aiding employees and visitors in locating and accessing elevators independently. This commitment to accessibility and safety reflected BHP’s dedication to fostering a safe and inclusive work environment.

The installation of stainless steel tactile indicators with carborundum at BHP’s facilities underscored Dottac’s commitment to accessibility and safety in industrial and corporate settings. These tactile indicators represented a commitment to making work environments more accessible and safer for all individuals, regardless of their abilities. BHP’s dedication to accessibility and safety, as demonstrated through its collaboration with Dottac, transformed its facilities into more inclusive and secure spaces.

Furthermore, the tactiles significantly contributed to reducing the risk of accidents and enhancing the confidence of employees, contractors, and visitors with visual impairments. By providing clear and tactile cues, they facilitated independent navigation in complex industrial settings, reducing the likelihood of mishaps.

The use of stainless steel tactile indicators with carborundum at BHP’s facilities in Western Australia was a significant milestone in enhancing accessibility and safety in industrial and corporate environments. The project not only made the facilities more accessible but also emphasized the importance of thoughtful design and tactile solutions in creating safer and more inclusive workplaces. BHP’s commitment to accessibility and safety sets a commendable example for the industrial sector, highlighting the significance of accessibility and safety in fostering a culture of inclusivity and well-being for employees and visitors alike.